NIR Trends: Photoluminescence Inspection of Photovoltaics with SWIR Imaging

Contactless machine-vision inspection using photoluminescence (PL) imaging with shortwave infrared (SWIR) cameras can help solar cell producers improve both efficiency and quality of their photovoltaic products. Inspection of silicon bulk ingots, sliced wafers, processed layers, and complete photovoltaic cells is possible with SWIR imaging. The PL emissions occur at the wavelengths associated with the semiconductor bandgap, which are visible to high-sensitivity, uncooled, indium gallium arsenide (InGaAs) cameras, even while imaging at video frame rates. This inspection technique illuminates the objects of interest with high optical power at one wavelength, and photons are absorbed in the bulk material. Some energy is lost as heat in the interaction with the molecular structure and the remaining energy causes a photon to be re-emitted at a longer wavelength. The uniformity and intensity of the resulting glow is sensitive to many parameters of the material, and of subsequent processing steps. In many cases, properties of the material, such as minority carrier lifetime, can be mapped from the PL image, and these maps will directly relate to how well the final product will perform as a solar cell.

SWIR photoluminescence imaging has several major advantages for machine vision inspection over visible and SWIR imaging of electroluminescence (EL).

- Contactless – PL inspection is performed without contacting the material being inspected.

- No or minimal sample preparation – 100 percent, on-line inspection can take place, at room temperature, at various point in the fabrication process, without disrupting the production flow.

- SWIR PL imaging works with raw, partially, and full-finished wafers – Alternatively, EL requires contact electrodes and is primarily used for finished-product quality control, by manufacturer and for in-coming inspection by system integrators.

- SWIR PL works with backside metalized wafers – The metal blocks SWIR imaging through the wafer, but SWIR PL inspection detects those defects with hurt minority carrier lifetime, without contact. When electrical contact is possible, SWIR EL actively reveals other defects that hurt efficiency, including cracks.

- Video frame rate acquisition up to 30 fps – SWIR cameras have high quantum efficiency (QE) at the prime silicon emission wavelengths, permitting imaging at 30 VGS frames per second or 60 ¼ BFA fps, unlike silicon cameras used for PL, which require frame exposure times of 1 to 30 seconds per image at similar resolutions.

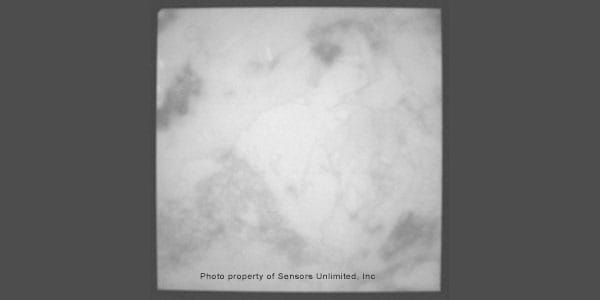

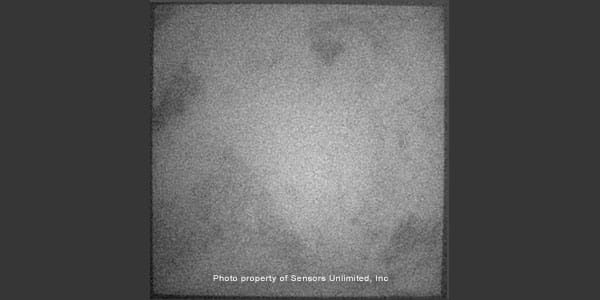

The image gallery below demonstrates the use of PL to find no-uniformities, and defects in the silicon wafers.

The PL images were acquired with illumination provided by four semiconductor diode lasers at 810 nm with overlapping diffused beams to achieve uniform illumination, one source per side. Approximately 30 W of illumination was used for Figures 1 and 3 of the L images shown, 60 W for Figure 4. The images were taken at different times using the same 16 mm f/1.8 lens, with the 810 nm excitation filtered at the lens by RG-1000 long pass filters (the cut-on wavelength was 1000 nm); one filter was used with the InGaAs camera, there were stacked when used with the silicon camera. The test station, silicon camera images and wafers were provided by the National Renewable Energy Labs (NREL) at Golden, CO.

Figure 1b:

Figure 2a:

Figure 2b:

Figure 3a:

Figure 3b:

Figure 4a:

Figure 4b:

Both Sensors Unlimited linescan and area cameras can be used for photoluminescence inspection of photovoltaic solar cells. For more information on this subject click here.

As seen in the 11/18/09 edition of the Photonics Online (www.photonicsonline.com) newsletter.

Recommended product categories

1024LDM Linescan Camera

1024LDH2 Linescan Camera